Windows serve as a crucial interface between a building’s interior and exterior environment, playing a fundamental role in energy efficiency and occupants’ comfort. In recent years, technological advancements have driven the development of new window types and energy-saving technologies, resulting in a diverse range of options for consumers.

When selecting new windows, it’s essential to consider a variety of factors that directly influence their energy efficiency and overall performance. One such crucial factor is the frame material, which can range from wood, aluminum, vinyl, to composite materials. Each material has its own advantages and disadvantages in terms of thermal insulation, durability, and cost. Additionally, glass characteristics, such as the number of layers, low-emissivity coating, and the presence of gas chambers, play a significant role in the energy efficiency of windows.

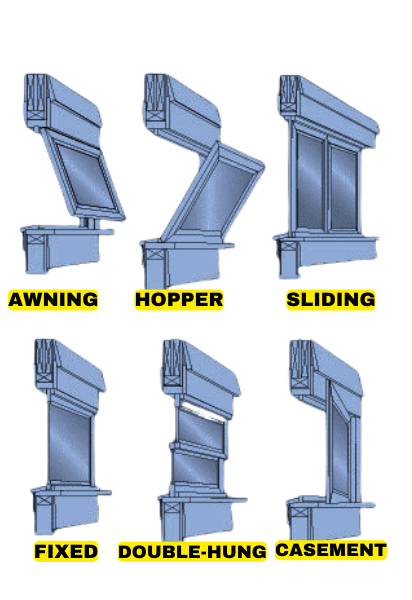

Another aspect to consider is the type of window operation, such as sliding, casement, awning, and pivot windows. Each operation type offers different levels of ventilation, ease of use, and air tightness. Furthermore, sealing technologies and spacers also play an important role in the energy efficiency of windows, ensuring a tight seal and minimizing heat transfer through the window edges.

It’s important to highlight that windows play a crucial role in a home’s energy efficiency, directly influencing energy consumption for heating, cooling, and lighting. Well-designed and installed windows can significantly reduce heat loss in winter and heat gain in summer, thereby providing a more comfortable indoor environment and reducing energy costs over time.

Ultimately, the choice of the right windows for a specific project depends on individual client needs, local climatic conditions, and available budget. By carefully considering all these factors, consumers can make informed decisions that not only reduce energy consumption and operational costs but also improve comfort and quality of life within their homes or buildings.

Frames and Sash

Enhancing the thermal resistance of the frame contributes significantly to a window’s overall energy efficiency, especially its heat loss rate or U-factor. All frame materials have their pros and cons, but materials like vinyl, wood, fiberglass, and certain composites offer better thermal resistance compared to metal.

Aluminum or Metal Frames

While metal or aluminum window frames are sturdy, lightweight, and low-maintenance, they conduct heat rapidly, making them poor insulators.

To mitigate heat transfer, metal frames should incorporate a thermal break—a plastic insulating strip positioned between the interior and exterior of the frame and sash.

Composite Frames

Composite window frames utilize composite wood materials such as particleboard and laminated strand lumber, sometimes combined with polymer plastics. These composites boast stability, comparable or superior structural and thermal properties to traditional wood, and enhanced resistance to moisture and decay.

Fiberglass Frames

Fiberglass window frames remain dimensionally stable and feature air pockets that can be insulated, offering superior thermal efficiency compared to wood or uninsulated vinyl.

Vinyl Frames

Constructed from polyvinyl chloride (PVC) with UV stabilizers to withstand sunlight degradation, vinyl window frames require no painting and exhibit good moisture resistance. The hollow chambers within vinyl frames can be filled with insulation, rendering them thermally superior to standard vinyl and wood frames.

Wood Frames

Wood window frames provide relatively good insulation but demand regular maintenance, although aluminum or vinyl cladding reduces upkeep needs. Metal-clad wood frames may exhibit slightly lower thermal performance.

Glazing or Glass

When it comes to energy efficiency in windows, the choice of glazing is paramount. Depending on factors like window orientation, climate, and building design, different types of glazing may be preferable for various windows in your home.

For detailed insights into glazing options, you can explore the Efficient Windows Collaborative, where you’ll find information on the specific properties and efficiency of different glazing options.

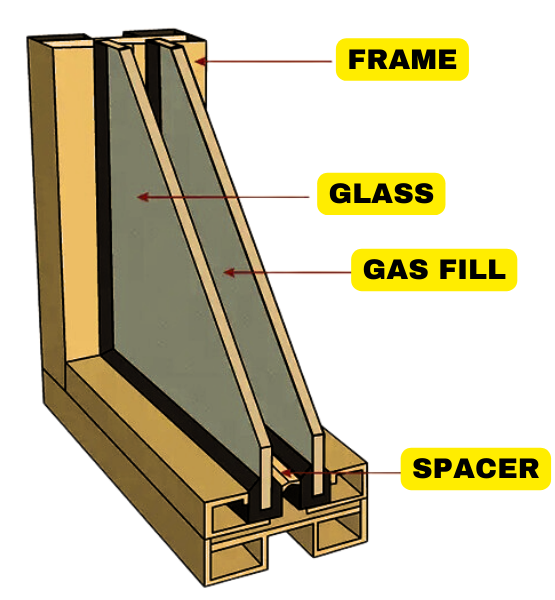

While older buildings commonly feature single glazing, nearly all new energy-efficient buildings utilize double or triple glazing units. These “insulating glazing units” (IGUs) offer a wide range of properties, determined by factors such as the glass type, coatings, gas fillings, and spacers.

Here are some common coatings and technologies you might encounter while shopping for windows:

Insulated

Insulated window glazing involves two or more glass panes separated and hermetically sealed to create an insulating air space. This primarily reduces the U-factor and also the solar heat gain coefficient (SHGC).

Low-Emissivity Coatings

Low-emissivity (low-e) coatings control heat transfer within the insulated glazing. While windows with low-e coatings generally cost slightly more, they can reduce energy loss by 30% to 50%.

These coatings, often made of microscopically thin metal or metallic oxide layers, are applied directly onto the glass surface. They lower the U-factor, manage daylight transmittance, and control solar heat gain. Different types of low-e coatings offer varying levels of solar gain and visible daylight transmission control.

Spectrally Selective Coatings

For climates where cooling loads are significant, spectrally selective coatings filter out a substantial portion of the sun’s non-visible infrared radiation while allowing full daylight transmission. This technology is particularly useful in maintaining comfortable indoor temperatures while optimizing natural light and views.

Gas Fills and Spacers

To mitigate heat transfer between a window’s interior and exterior, the space between glazing layers, typically around 1/2″, is infused with either argon or krypton gas—both inert, non-toxic, and transparent.

Argon reigns as the most prevalent choice due to its cost-effectiveness and satisfactory performance within the standard 1/2″ space. However, krypton becomes advantageous when dealing with thinner spaces, typically around ¼ inch, as it boasts superior thermal performance albeit at a higher cost.

Spacers, complemented by sealants, maintain the requisite distance between glazing layers while accommodating thermal expansion and pressure differentials. Furthermore, they serve as a barrier against moisture and gas leakage.

An array of spacers is available, each exerting varying impacts on the window U-factor. Particularly noteworthy are “warm edge” spacers engineered to reduce the window U-factor and mitigate condensation along the window’s edge. For comprehensive insights into different spacer types, individuals can refer to the Efficient Windows Collaborative.

Operating Types

The operational functionality of windows represents another crucial aspect to consider. Since all operable windows can potentially introduce unwanted air leakage, which compromises a home’s energy efficiency, the choice of operator type can significantly impact overall energy consumption. Air leakage rates are contingent upon the type and quality of weatherstripping and seals, with tendencies to increase over time due to operational usage. Traditional operating types encompass:

Awning: Hinged at the top and opening outward. Their sash closes by pressing against the frame, contributing to lower air leakage rates compared to sliding windows.

Hopper: Hinged at the bottom and opening inward. Similar to awning and casement windows, they tend to exhibit lower air leakage rates as the sash seals against the frame.

Single- and double-sliding: Both sashes slide horizontally in double-sliding windows, while only one sash moves in single-sliding windows. These sliding windows typically have higher air leakage rates than projecting or hinged windows like single- and double-hung varieties.

Fixed: These windows feature non-opening panes. When correctly installed, they are airtight but may not be suitable in areas where window ventilation and egress are desired.

Single- and double-hung: Both sashes slide vertically in double-hung windows, with only the bottom sash moving upward in single-hung windows. These sliding windows generally exhibit higher air leakage rates compared to projecting or hinged windows.

Casement: Hinged at the sides, they open outward. Similar to awning windows, casement windows often boast lower air leakage rates as the sash seals against the frame.

In conclusion, the energy efficiency of windows is crucial for the comfort and sustainability of buildings. By considering factors such as frame materials, types of glass, and operations, it’s possible to optimize energy performance and reduce costs. With advancements in glazing technologies, spacers, and operation types, consumers have access to more efficient options. Investing in high-efficiency windows not only reduces energy consumption but also enhances occupants’ comfort and quality of life, contributing to a more sustainable environment.

Discover the perfect windows to elevate your home’s energy efficiency with our Energy Audit. As passionate advocates for energy conservation, we provide complimentary audits designed to optimize your household’s efficiency. Join us in saving costs, preserving resources, and making a positive impact on the environment.

If you reside in New York, it’s worth noting that the government offers various incentives to help you make your home more energy efficient. These incentives include tax refunds, discounts, and financing options through initiatives like Clean Heat, Comfort Home, and GJGNY Financing. These programs aim to support residents in upgrading their homes to be more environmentally friendly and cost-effective in terms of energy consumption.

We’re here to support you in navigating these opportunities by verifying your eligibility and assisting with the application process if you qualify. By taking proactive steps, we can collectively work towards a more sustainable and cost-effective future.